Wafer Technology: At the heart of the new future of the semiconductor industry

2025-04-12

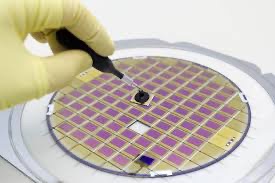

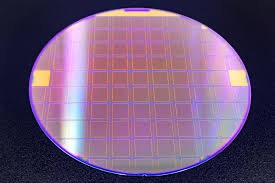

What is a wafer?

Wafer is the basic material of semiconductor manufacturing, usually made of high-purity silicon cut into thin sheets. These round sheets are precision-machined and become platforms for carrying integrated circuits. The size, purity and manufacturing process of the wafer directly determine the performance and cost of the chip. Common wafer sizes include 6-inch, 8-inch, and 12-inch wafers, and more advanced processes are driving the development of larger wafers.

The importance of wafer technology

1. The cornerstone of performance improvement

The quality of the wafer and the manufacturing process determine the performance of the chip. As process technology shrinks from 10 nanometers to 3 nanometers or even 2 nanometers, wafers require higher flatness and lower defect rates to support more sophisticated circuit designs. This is directly driving leaps in processor speed, energy efficiency and AI computing power.

2. Expansion of application scenarios

Advances in wafer technology allow chips to adapt to more scenarios. For example, low-power chips provide longer battery life for iot devices; High-performance chips provide powerful computing power for data centers and cloud computing; And specialized chips (ASics) are making waves in areas such as autonomous driving and blockchain.

3. The core of supply chain

Wafer manufacturing is the most critical link in the semiconductor supply chain. From wafer production to chip design, manufacturing and packaging, every step depends on the support of high-quality wafers. Especially in the context of the tight global supply chain, the stable supply of wafers has become the focus of the industry.

Latest trends in wafer technology

* Larger size wafers: 12-inch wafers have become mainstream, but the development of 18-inch wafers is accelerating. Larger sizes mean higher productivity and lower unit costs.

* Advanced process breakthrough: The mass production of processes of 3 nm and below puts higher requirements on wafer purity and manufacturing equipment, and the popularity of EUV (extreme ultraviolet lithography) technology is changing the rules of the game.

* Exploration of new materials: In addition to silicon wafers, new materials such as silicon carbide (SiC) and gallium nitride (GaN) are emerging, especially in the field of power devices and new energy.

* Sustainability: Wafer manufacturing is energy-intensive, and the industry is actively exploring green manufacturing technologies to reduce environmental impact by optimizing processes and recycling materials.

Why choose our wafer solutions?

In a highly competitive wafer technology market, we are committed to providing our customers with high-performance, reliable and sustainable wafer products:

* High quality assurance: Using advanced inspection technology to ensure zero defects on the wafer surface to meet the most demanding process requirements.

* Customized services: from size to material, we provide flexible customized solutions to help customers quickly achieve product innovation.

* Global supply chain support: Through a comprehensive logistics network and production capacity, ensure stable supply and reduce customer risk.

* Green Commitment: We invest in energy efficient technologies and recycling to help our customers achieve their sustainability goals.

Look to the future

Wafer technology is not only the cornerstone of the semiconductor industry, but also the key to driving the digital economy, artificial intelligence and green energy. With the rise of emerging fields such as quantum computing, 6G communication and metacomes, wafer technology will usher in a bigger stage. We believe that through continuous innovation and collaboration, wafers will inject stronger momentum into the global development of science and technology.

Join the wafer revolution and open a new chapter in science and technology!

If you are interested in our wafer products or solutions, please visit our website or contact us for more details. Let's join hands to create a brilliant future for the semiconductor industry!